History of a “savoir-fer”

Organized in village communities, the Dogon are a farming society made up of hereditary chiefdoms based on control of the land. The land is a fundamental element in the collective identity of the Dogon. Their tools are mainly iron hoes and axes. Mastery over extraction and reduction of iron ore and the shaping of objects were major challenges in this rural society.

The spread of the use of iron had a significant impact on the structure of societies and territorial management. The Dogon Country, a place of many influences, possesses a cultural heritage remarkable for the number and variety of siderurgical remains, forming a favorable context to analyze the formation of smith castes and the structure of iron industry.

Our approach is both extensive and diachronic. It is based on the analysis of oral traditions and the archaeological material recovered during surveys and excavations.

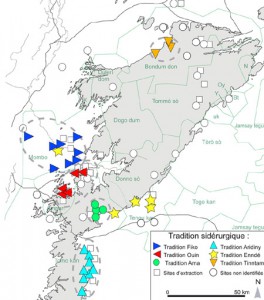

Fig.2 Metallurgical traditions, extraction and reduction sites discovered in the Dogon Country. DAO C. Robion-Brunner

Who are the Dogon smiths?

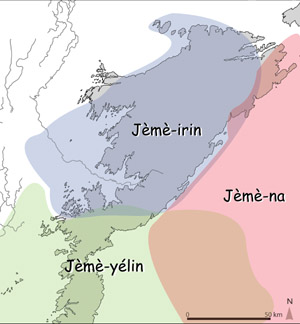

Preceding research had identified three smith casts in the Dogon Country: the Jèmè-na, the Jèmè-irin and the Jèmè-yélin (fig. 1). These are defined by their technical knowledge and place of residence. Only reduction sites located on the Seno plain and the southern plateau are discussed. The Bandiagara plateau was presented as lacking any evidence for siderurgical production; the Jèmè-irin would have thus had to obtain iron from the Jèmè-na.

Reconstruction of the migration routes using the patronyms shows that the Jèmè-irin had their own history, but dependent on that of the farmers, and a complex apprenticeship process. They belong to a non-hermetic caste for which the marriage rules changed according to economic, political and social circumstances.

In the Dogon Country, this caste is formed from a local population group to which were successively added populations coming mainly from the Inland Niger Delta. In the beginning, these individuals did not all belong to the social category of smiths. On the basis of a voluntary social transformation or forced by the Dogon, many local Dogon or foreign farmers, as well as slaves, became iron specialists to meet the economic needs.

Metallurgy on the plateau

During our fieldwork, more than 50 siderurgic complexes were inventoried and located on the plateau and the Bandiagara escarpment. Their study demonstrates the quantity and variety of siderurgic remains present and identifies six metallurgical traditions : Fiko, Ouin, Ama, Aridinyi, Enndé and Tinntam) (fig. 2).

These traditions show several points of relatedness from a technological point of view. All of the furnaces have natural ventilation. The reduction method is a direct procedure with the separation of slag and iron. Nevertheless, they present different methods for removing slag. Vertical separation (Aridinyi and Enndé) and lateral separation (Fiko, Ouin, Ama and Tinntam) were both recorded; these two types of technology were still in practice at the beginning of the 20th century.

Reduction sites have slag heaps of varying size. The Enndé tradition is singled out by scattered small slag heaps (fig. 3). This production seems sporadic and associated with seasonal activity, and not established across the territory. The Ouin and Ama traditions group sites with low heaps (fig. 4). Production was regular and aimed at local consumption.

The spatial organization of the Aridiny and Tinntam traditions is entirely different. These traditions group sites focused on regular production with local distribution and others on intensive production for regional distribution. The Fiko tradition is noted for its large heaps of waste, from 2,000 to 80,000 m3 per complex (fig. 5). This tradition constitutes a true siderurgic district. Established on the western margin of the plateau, this intensive production would have been aimed at a market outside the Dogon Country.

The history of Dogon siderurgy is still difficult to perceive. However, radiocarbon dates at Fiko and Gumbessugo sites demonstrate that this activity was practiced at least since the 11th century AD, earlier than the arrival of the Dogon in the 13th-15th centuries.

Who are the metallurgists?

In most ethnographic research, the term “smith” covers a dimension more social and symbolic than technological. To identify the different participants, one must take into account and isolate the principal stages of the process, the destination of production and the status of the actors.

The world of siderurgy includes only two social categories, farmers and smiths. They can work together or apart. For the ore extraction phase, the holders or land and magical knowledge are the farmers; the smiths have the technological knowledge. Mining work requires a large work force, which is made up of both farmers and smiths.

For reduction, land holders are always farmers. In contrast, the smiths now have both magical and technological knowledge. At siderurgical sites for local and regional distribution, the smiths along manage the technical operation. At sites for extra-regional distribution, farmers are assisted by smiths from neighboring villages, while their own smiths treat the bloom (the blocks of wrought iron).

The forge is itself a world entirely organized by the smiths (fig. 6). As a consequence, the identity of the Dogon metallurgists is not unique, but multiple and it differs according to the status and stages of production.